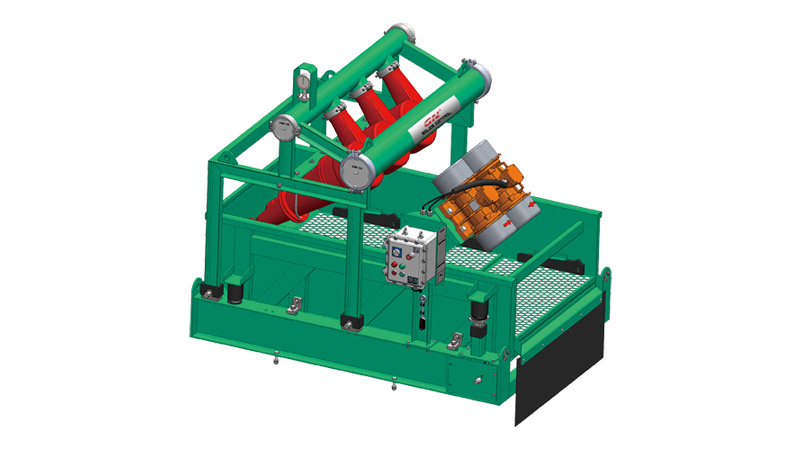

Desander in solids control is a crucial component in the process of drilling fluids management within the oil and gas industry. Its primary purpose is to remove solid particles, such as sand and silt, from drilling fluids to maintain the desired properties of the fluid and enhance the efficiency of drilling operations. The main function of a desander is to separate and remove larger solid particles, typically ranging from 40 to 100 microns, from the drilling fluid. By removing these solids, the desander helps maintain the rheological properties and stability of the drilling fluid, ensuring it can effectively carry cuttings to the surface. The core component of a desander is a set of hydrocyclones arranged in a manifold. These cyclones use centrifugal force to separate solid particles from the drilling fluid. Drilling fluid containing solids enters the desander through an inlet pipe, and the cleaned fluid exits through an outlet pipe. The separated solids are discharged through the underflow port, while the cleaned drilling fluid exits through the overflow port. Drilling fluid, often called mud, enters the desander unit at high pressure through the inlet. The hydrocyclones in the desander create a swirling motion, causing heavier solid particles to move toward the outer wall and exit through the underflow port. The cleaned drilling fluid, with reduced solid content, exits through the overflow port. Desander solids control is typically part of a larger solids control system that includes other equipment like shale shakers, desilters, and centrifuges. These components work together to ensure the drilling fluid meets specified criteria for reuse in the drilling process. By maintaining the quality of the drilling fluid, desander solids control contributes to efficient drilling operations. Removing abrasive solids helps protect downstream equipment, such as pumps and mud motors, from wear and damage. Regular maintenance is essential to ensure the proper functioning of desander solids control equipment. This includes monitoring and cleaning the cyclones and checking for any wear and tear. Desanders play a crucial role in the overall solids control process, helping to enhance the efficiency and cost-effectiveness of drilling operations in the oil and gas industry. At GN we provide our customers with customized desanders, according to their functions and operations. We can attach them to shale shaker, and with desilters or by it self. Keeping your operations running sound and well.