Modular Design for Efficient Sludge Separation and Oil Recovery

GN Solids Control has successfully delivered a containerized oil sludge treatment system to a client in Europe, specifically designed for crude oil tank cleaning and waste oil recovery. The system is built with a modular layout to allow easy transportation, rapid deployment, and reliable performance in various field conditions.

System Configuration Overview

The complete system includes:

-

Two 20FT Pre-Mixing Tank Modules: These units are used to pre-heat and homogenize the tank bottom sludge, preparing it for separation.

-

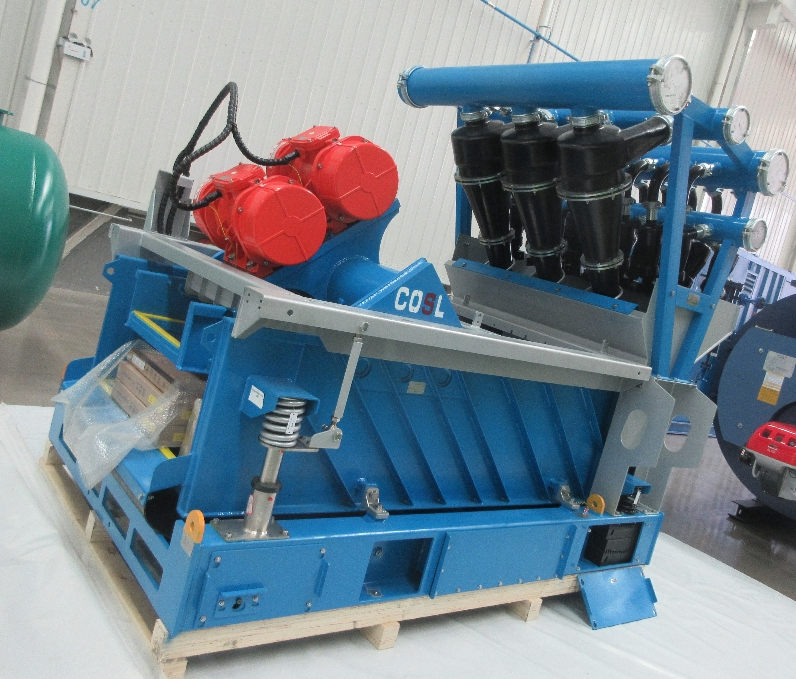

One Double Deck Vibrating Screen Module: Designed to remove large particles and debris from the sludge before entering further treatment stages.

-

One Hydraulic Decanter Centrifuge Module: Equipped with GN’s high-speed centrifuge, this module separates fine solids from oil and water with high efficiency.

-

One Automatic Flocculation Dosing Module: Improves solid-liquid separation by dosing chemical agents to promote fine particle aggregation.

This containerized system enables an integrated and continuous treatment process, maximizing the recovery of usable oil while minimizing waste. It is especially suitable for refineries, tank farms, and oil depots that need onsite sludge reduction and recovery operations.

The successful delivery reflects GN’s technical strength in offering turnkey oil sludge treatment systems that comply with European standards for safety, mobility, and environmental protection. GN continues to serve global clients with reliable, customized waste management solutions