GN Solids Control introduces the GNLW364-FHD Hydraulic Drive Decanter Centrifuge, designed to meet the demanding requirements of starch production. With a food-grade polished interior and a high-torque hydraulic drive system, this centrifuge ensures efficient separation of high-viscosity and high-concentration materials.

Precision Engineering for Food-Grade Applications

To comply with food processing standards, the bowl and screw are polished to ensure a smooth and hygienic surface. The centrifuge is also equipped with temperature and vibration sensors and an automatic bearing lubrication system, providing stable performance and minimal maintenance.

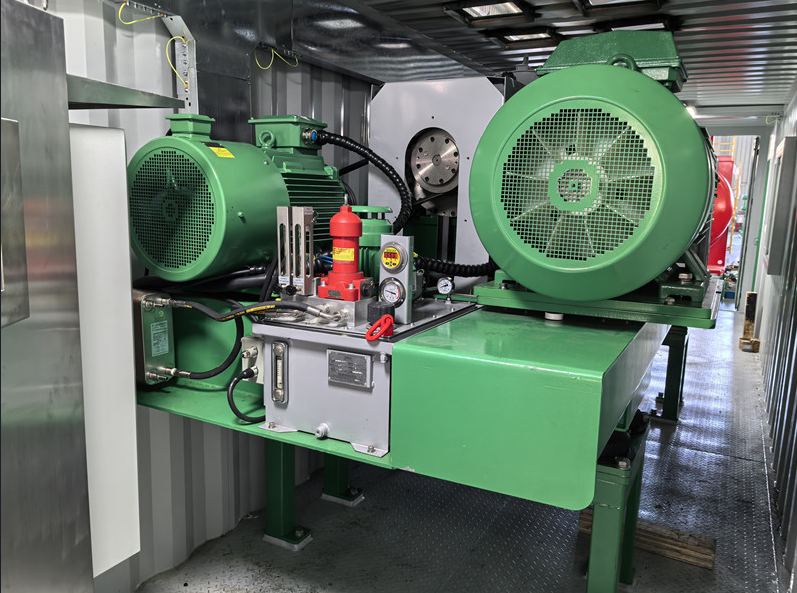

Advanced Hydraulic System for High Efficiency

Powered by the Swiss-made Viscotherm hydraulic drive system, this centrifuge delivers exceptional torque and precise control. Key features include:

- Maximum system pressure: 250 bar

- Maximum torque: 5162 Nm

- Maximum rotational speed: 4500 RPM

- Maximum differential speed: 70 RPM

- Air cooling system for enhanced reliability

With its high-power hydraulic system and adjustable rotation speed, the GNLW364-FHD is an ideal solution for starch separation and other industrial processing needs.

For more information, contact GN Solids Control today!