GN has delivered a highly efficient sludge dewatering screw press package to a sewage treatment plant in Europe. This package includes the advanced GNDL303 screw press and the reliable GNSJY2000 chemical dosing unit, providing an integrated solution for effective sludge management in municipal and industrial wastewater treatment applications.

Highlights of the Solution

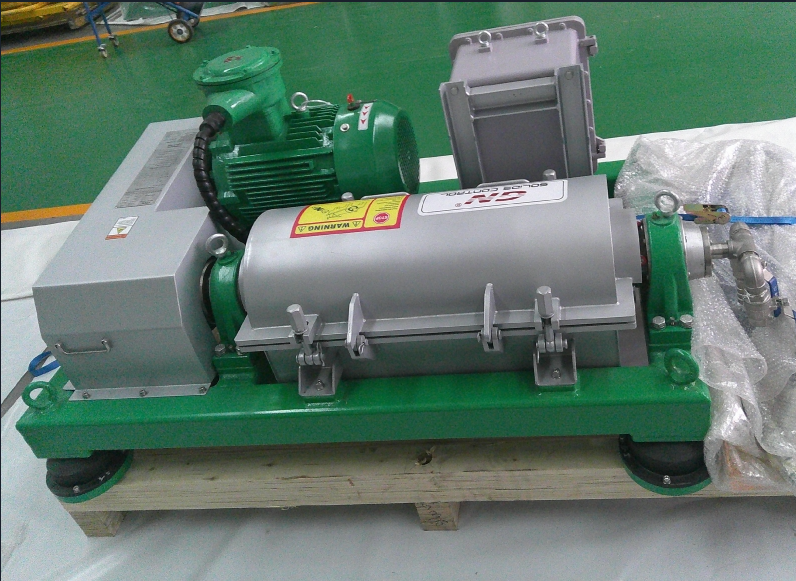

- GNDL303 Screw Press

The GNDL303 screw press is designed to deliver superior dewatering performance while maintaining low energy consumption and quiet operation. Its compact structure and durable components make it an ideal choice for facilities aiming to reduce sludge volume and disposal costs. The system ensures stable operation with minimal maintenance requirements. - GNSJY2000 Chemical Dosing Unit

The GNSJY2000 chemical dosing unit automates the preparation and dosing of flocculants, improving sludge conditioning and separation. This unit enhances the efficiency of the dewatering process while minimizing chemical consumption, contributing to a cleaner and more sustainable operation.

This complete sludge dewatering package is a testament to GN’s commitment to delivering high-quality and environmentally conscious solutions for wastewater treatment facilities worldwide.