GN Solids Control recently completed the delivery of a complete HDD mud system package to a customer in the Middle East. The system is designed to support horizontal directional drilling (HDD) operations by providing reliable and continuous mud recycling and mixing functions on site.

System Components:

-

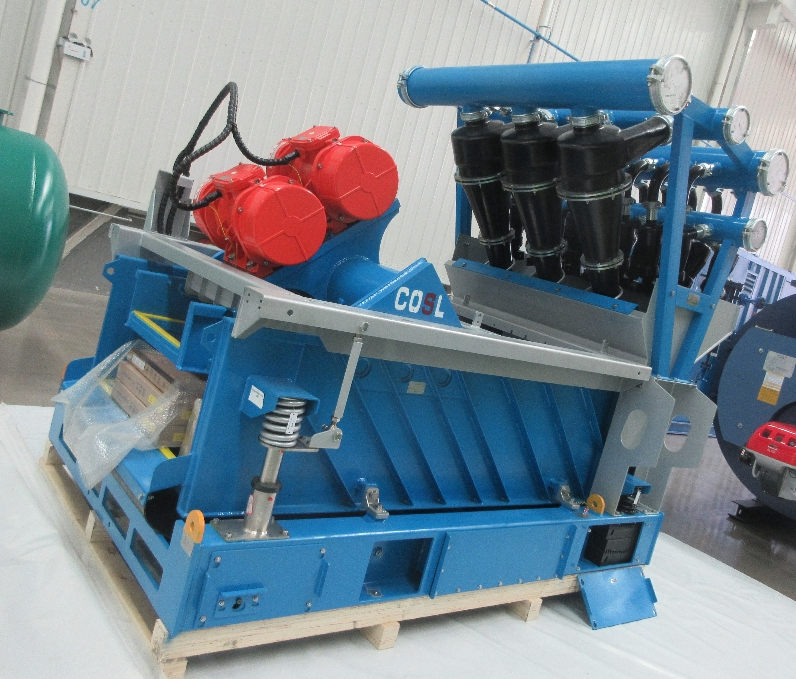

Mud Cleaning Unit

The unit is equipped with high-performance GN shale shakers and an integrated mud cleaner (desander + desilter) to remove coarse and fine solids from drilling mud efficiently. This three-stage separation process helps maintain mud quality and protect downstream drilling equipment. -

Mud Mixing Tanks

Multiple mixing tanks are included in the package, each integrated with mud agitators and jet mixing hoppers. This allows the operator to blend drilling additives on-site, keeping the mud properties within the required range throughout the drilling process. -

Shale Shakers

GN’s linear motion shale shakers are built for high G-force and long service life. They are known for easy screen replacement, high capacity, and stable performance—ideal for tough drilling conditions in desert environments.

Designed for HDD Applications

This system is specifically engineered for HDD contractors working in regions where water resources are limited and environmental standards are strict. By recycling and reusing drilling mud, the system not only reduces fluid costs but also minimizes waste discharge.

GN’s Commitment to the Middle East Market

As a trusted supplier in the trenchless drilling industry, GN Solids Control continues to expand its presence in the Middle East by offering complete, modular mud systems that meet both performance and environmental demands.

For more information about our HDD solutions, contact us at www.gnsolidscontrol.com