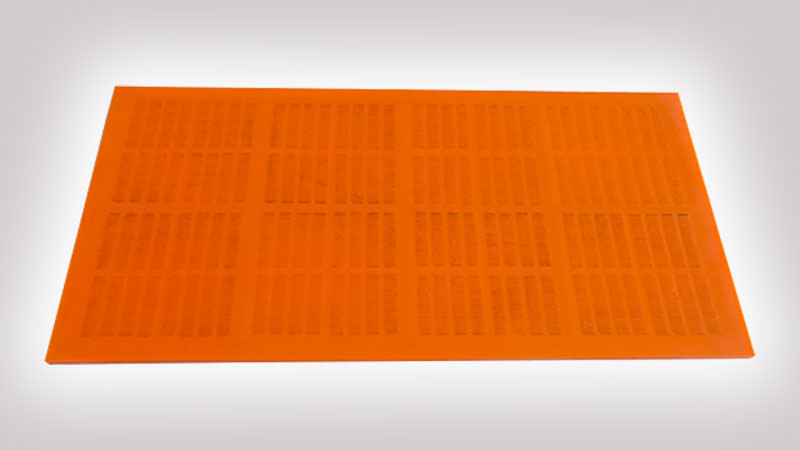

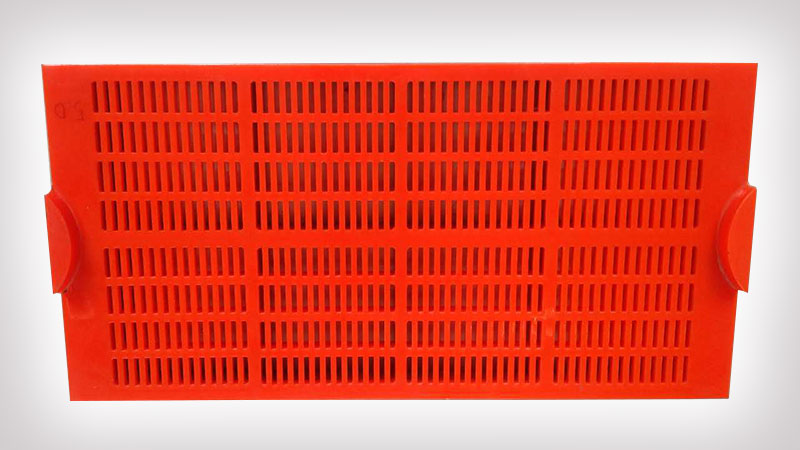

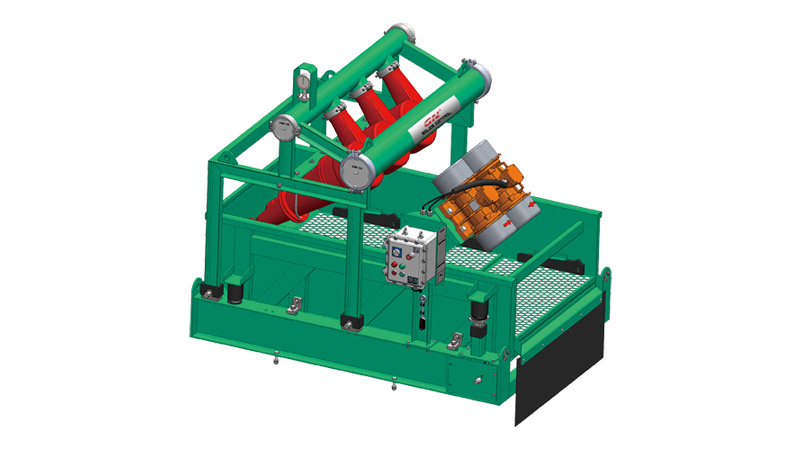

An oil and gas cutting dryer, also known as a cuttings dryer, is a critical piece of equipment used in the process of drilling for oil and gas. During drilling operations, drilling mud or drilling fluid is used to lubricate the drill bit, carry cuttings (rock chips) to the surface, and provide stability to the wellbore. However, this drilling mud becomes contaminated with drill cuttings and other solid particles as it circulates through the well. The oil and gas cutting dryer is designed to separate these solid particles from the drilling mud, allowing for the reuse of the mud and the disposal or further treatment of the cuttings. This separation process helps to maintain drilling efficiency, reduce environmental impact, and comply with regulations regarding drilling waste disposal. The basic operation of a cutting dryer involves several stages. Feed Inlet is the contaminated drilling mud, along with the drill cuttings, enters the cutting dryer through a feed inlet. Screening and separation processes inside the cutting dryer, the mud and cuttings pass through a series of screens or sieves. These screens allow the mud to pass through while retaining the solid cuttings. Drying stage occurs after separation, the cuttings are subjected to a drying stage. This can involve centrifugal force or other mechanisms to remove excess moisture from the cuttings, making them easier to handle and transport. Discharge of dried cuttings occur once dried, the cuttings are discharged from the cutting dryer, typically into a collection bin or conveyor for further processing or disposal. Recovery of clean mud happens when the cleaned drilling mud, free from solid particles, is collected and returned to the drilling operation for reuse. Oil and gas cutting dryers come in various designs and configurations, including vertical and horizontal models, depending on the specific requirements of the drilling operation. They play a crucial role in the overall efficiency and environmental stewardship of oil and gas drilling operations by facilitating the recycling of drilling fluids and reducing the volume of waste generated. It can be used for oil based mud or water based mud. In order to be used in the water based operation, it needs a special water injection system for not getting build up or the mud causing it to jam. With the best products used to develop our system, such as our bearings from FAG, we have a great product with amazing productivity.