GN Solids Control is a specialist for mud solids control and drilling waste management, as well as industry waste management. GN Solids Control have its own R&D (research and development) department to focusing on the latest technology of the field. GN Solids Control owns different sizes of decanter centrifuges to suits for different separation.

GN Solids Control waste management system can used to treat waste water, waste oil, waste drilling mud, drilling waste no matter in yard, or in the rigs sites. Customers recognize that GN Solids Control company provides solutions for different type of waste. GN Solids Control’s target is to offer a complete system which can treat different kinds of waste and minimize or have zero disposal. For customers who are are looking for a system that can recover the valuable components of different kinds of waste, GN Solids Control is a good choice to them. Below are some of the types of waste material that GN Solids Control waste management system can handle and treat.

• Used or discarded oil-based drilling muds (i.e., OBMs), as well oil base cuttings

• Waste fuels and hydrocarbon mixtures (e.g. diesel, gasoline);

• Oily waste/wastewater from maintenance and repair shops;

• Discarded paints, thinners and solvents from rig maintenance;

• Wastewater and solvents from cleaning tubular connections;•

• Rig wastewater and low-gravity solids from solids control;

• Waste and Wastewater drainage from material and chemical storage facilities;

• Wastewater from rig-associated equipment cleaning/maintenance;

• Wastewater from machinery space drainage;

• Oily wastewater and contaminated soils from accidental spills.

GN Solids Control main equipment for drilling waste management are as below:

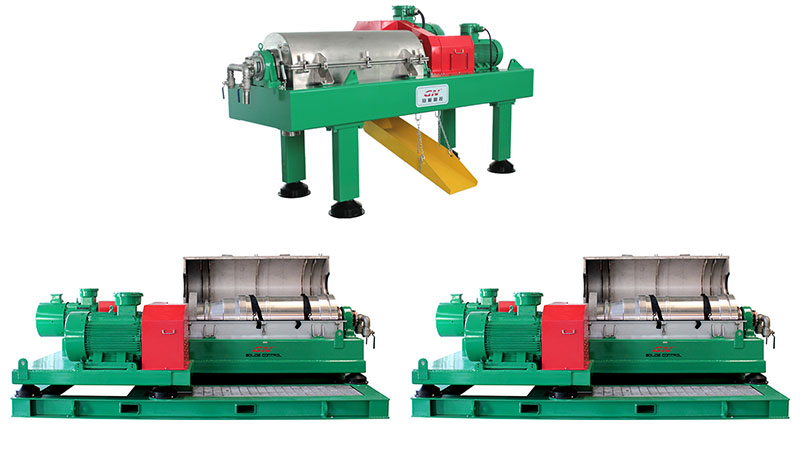

1) Different sizes of decanter centrifuges and tricanter centrifuges vary from 9 inch to 30 inch

2) High G drying shale shaker

3) Vertical cuttings dryer

4) Chemical dosing system (dewatering unit) for powder chemical mixing and liquid chemical mixing, like PAM, PAC, polymer…

5) Screw conveyors with safety device

6) Vacuum transfer pump

Очень стильные новости мировых подиумов.

Все события самых влиятельных подуимов.

Модные дома, бренды, haute couture.

Свежее место для стильныех людей.

https://ulmoda.ru/

Самые свежие новости моды.

Все новости лучших подуимов.

Модные дома, лейблы, высокая мода.

Интересное место для трендовых людей.

https://paris.luxepodium.com/

Fashion, luxe, lifestyle

Best style home for hypebeasts and stylish people.

Industry news, events. Best collections, collaborations, limited editions.

https://watch.lepodium.net/

Несомненно трендовые новинки моды.

Исчерпывающие эвенты мировых подуимов.

Модные дома, лейблы, высокая мода.

Новое место для модных людей.

https://richlifestyle.ru/

Наиболее трендовые новости подиума.

Все события самых влиятельных подуимов.

Модные дома, лейблы, высокая мода.

Лучшее место для трендовых людей.

https://furluxury.ru/

Наиболее свежие новинки мира fashion.

Важные новости мировых подуимов.

Модные дома, лейблы, высокая мода.

Приятное место для модных людей.

https://fe-style.ru/

Абсолютно все свежие события часового искусства – свежие коллекции известных часовых компаний.

Абсолютно все варианты хронографов от доступных до очень роскошных.

https://watchco.ru/

Точно трендовые события мира fashion.

Абсолютно все новости известнейших подуимов.

Модные дома, бренды, высокая мода.

Новое место для трендовых хайпбистов.

https://balenciager.ru/

Очень актуальные новинки индустрии.

Все новости известнейших подуимов.

Модные дома, торговые марки, гедонизм.

Приятное место для трендовых людей.

https://outstreet.ru/

Избранные трендовые события часового искусства – актуальные модели легендарных часовых брендов.

Все модели хронографов от дешевых до ультра премиальных.

https://bitwatch.ru/

LeCoupon: актуальные новости для любителей модного шоппинга

Лента новостей, события, модные луки, эвенты, коллекции, подиум.

https://qrmoda.ru/

LeCoupon: актуальные события для любителей fashion шоппинга

Новости, события, стильные луки, эвенты, коллекции, показы.

https://qrmoda.ru/

medicine in mexico pharmacies: mexican pharmacy – mexican mail order pharmacies

pharmacies in mexico that ship to usa

https://cmqpharma.online/# п»їbest mexican online pharmacies

mexican online pharmacies prescription drugs

canadian drugs pharmacy: safe canadian pharmacies – canadian pharmacy service

http://foruspharma.com/# buying prescription drugs in mexico

best india pharmacy indian pharmacies safe indian pharmacy online

buying prescription drugs in mexico online: mexican pharmacy – pharmacies in mexico that ship to usa

mexico drug stores pharmacies: mexican rx online – mexican drugstore online

cheapest online pharmacy india online pharmacy india buy medicines online in india

https://canadapharmast.com/# canadian pharmacies online

canadian pharmacy world reviews: canadian pharmacy prices – canadian king pharmacy

canadadrugpharmacy com reputable canadian online pharmacies canadian 24 hour pharmacy

india pharmacy mail order: indian pharmacy online – india pharmacy mail order

http://canadapharmast.com/# canadian pharmacy near me

canadian discount pharmacy: canada drugs online – canadian pharmacy in canada

buy medicines online in india: indian pharmacy – pharmacy website india

http://ciprodelivery.pro/# п»їcipro generic

doxycycline coupon: doxycycline no script – doxycycline 100mg tablets coupon

https://ciprodelivery.pro/# ciprofloxacin generic

https://paxloviddelivery.pro/# paxlovid price

buy cipro: buy ciprofloxacin over the counter – ciprofloxacin mail online

https://paxloviddelivery.pro/# paxlovid price

https://doxycyclinedelivery.pro/# doxycycline singapore

cost generic clomid without a prescription: clomid prices – can i purchase generic clomid without prescription

https://amoxildelivery.pro/# how much is amoxicillin prescription

paxlovid cost without insurance: paxlovid for sale – paxlovid cost without insurance

https://doxycyclinedelivery.pro/# doxycycline 50 mg price australia

https://doxycyclinedelivery.pro/# doxycycline pills price in south africa

how much is amoxicillin: amoxicillin tablet 500mg – amoxicillin 250 mg

https://clomiddelivery.pro/# can i get cheap clomid online

amoxicillin 500 mg for sale: how to get amoxicillin over the counter – amoxicillin capsules 250mg

buy amoxicillin without prescription: over the counter amoxicillin canada – amoxicillin 825 mg