GN Solids Control: Leading the Way in Mud Recycling

GN Solids Control is a leading manufacturer of Horizontal Directional Drilling (HDD) Mud Equipment and Mud Recycling Systems. Our systems are widely used in HDD and CBM drilling operations in countries such as Australia, Indonesia, and India. With branches in Beijing, Houston, and Brisbane, we offer comprehensive mud recycling services and spare parts globally.

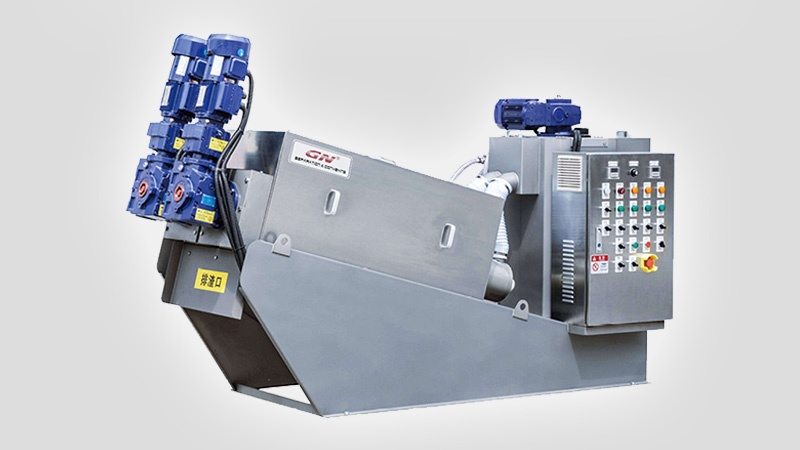

G Series Self-Contained Mud Recycling System

Complete Line of Mud Systems

Our G Series includes a range of self-contained mud recycling systems: GNMS-200GPM, GNMS-350GPM, GNMS-500GPM, GNMS-1000GPM, and GN1500GPM. These systems are designed for efficiency and integration, providing cost-effective solutions from a single source—GN Solids Control Factory.

Compact and Transportable

Our systems feature a small footprint design with fast connections for removable parts. Most components are fixed during transport, adhering to transport regulations. This ensures quick setup and mobility, crucial for on-site operations.

Reliable Customer Service

We provide installation and training services with experienced engineers, ensuring seamless integration and operation of our systems. Our mud tanks come in flexible options: skid-mounted, trailer-mounted, or hydraulic jack-up, to suit various operational needs.

Phases of Mud Recycling

- Shale Shaker: The first phase, separating solids larger than 100 microns.

- Desander: The second phase, separating solids up to 50 microns.

- Desilter: The third phase, separating solids up to 20 microns.

- Decanter Centrifuge: The fourth phase, separating solids up to 2-5 microns.

Additionally, our systems include mud agitators, mud guns, mixing pumps, and transfer pumps to ensure efficient mud recycling.

Custom Solutions for Trenchless Projects

Besides standard systems, GN Solids Control also offers customized mud recycling solutions tailored to specific drilling contractor applications, ensuring optimal performance and efficiency for various trenchless projects.