GN Solids control is a leading manufacturing on drilling waste hazardous material transfer. GN offers turnkey solution for different hazardous waste generated from oil field.

Below are some major equipment popularly for drilling waste handling.

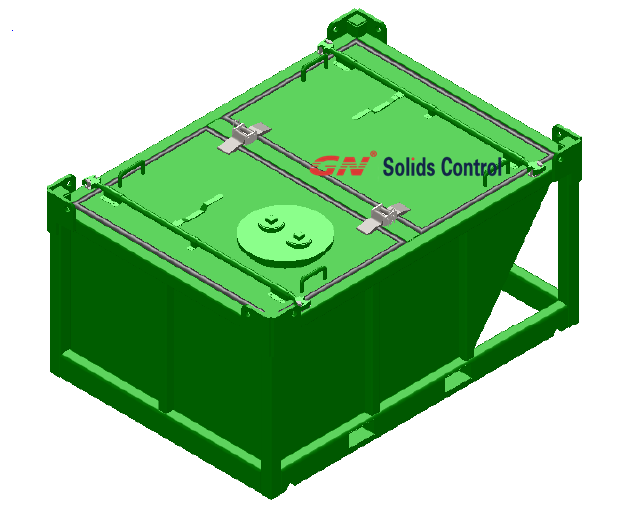

Item 1: Drilling waste mud and cuttings container

1) The drilling cuttings can be used to collect cuttings from solids control equipment: shale shaker, mud cleaner, desander, desilter and centrifuge, and move to drilling cuttings treatment system for process.

2) The container can be used to collect drilling cuttings from vertical cuttings dryer, High G dryer, and drilling waste high speed centrifuge, and move to TDU or stabilization unit for treatment.

3) The container can be used to store and take waste mud and cuttings from offshore platform and take to the onshore yard waste management system for treatment.

4) The top cover sealing type drilling cuttings container can be used to store and handling hydrocarbon contaminated drill cuttings.

Item 2: Drilling cuttings stabilization unit

The GN drilling cuttings solidification or stabilization unit can be used as the final treatment of drilling cuttings or waste sludge. The stabilizer unit can be used after the drying treatment equipment, like vertical cuttings dryer, high G drying shaker, drilling waste big bowl or high speed decanter centrifuges.

Items 3: Drilling waste Vertical cuttings dryer

Vertical Cutting Dryer utilize centrifugal force to dry drilled solids in oil or synthetic base fluids. A stainless steel screen bowl treat the drilling waste mud with cuttings and waste oil, the centrifugal force can be up 900RPM with G force to 420G or super high speed 1200RPM with G force 750G. Liquid is forced through the screen bowl openings, but the solids and cuttings will be removed by the angled flights attached to the cone, as the cones rotate slightly slower than the bowl. Tungsten carbide material protects the flights from abrasive solids and ensures long operational life. This aids in maintaining a constant gap between the scroll and screen bowl, which is crucial for proper operation.

I was studying some of your content on this site and I believe this website is rattling instructive!

Keep on posting.Raise range