GN Solids Control have a commonly clients from overseas marketplace. Recently, we have one consumer from Thailand bought one placed 500gpm mud cleaning system for HDD project. The customer is GN old buyer who have used our solids control equipment in about 2 yrs before. The drilling mud system is working for the government pipeline project.

The particular 500gpm drilling mud system including below components:

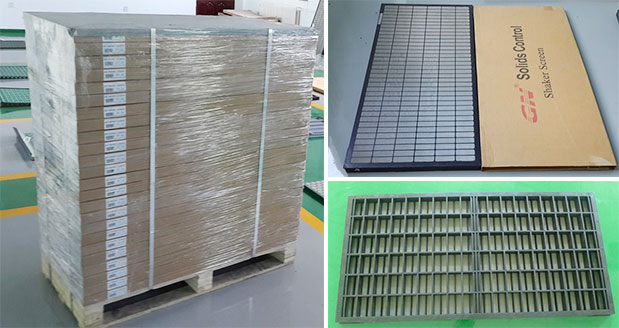

1) Shale shaker . The 4 panel shale shaker with longer shaker deck can treat the particular drilling mud in a lot better performance. The composite content shaker screen is alternative to Swaco Mongoose shaker. This kind of model shaker GNZS594 set have been used for CNPC, Sinopec, GSE, etc . many significant drilling companies. The opinions is very good, reasonable price tag and very high efficiency effectiveness.

2) Mud cleaner. The particular mud cleaner is with a single same GNZS594 series shaker, with one set desander cone and 8pcs desilter cones. The mud cleaner is three in one device, much compact design, in addition to good performance.

The mud cleaner need two units centrifugal pump for nourishing the desander cone and desilter cones.

3) Decanter centrifuge

For necessary oil drilling field, Most of consumer will need 2 sets decanter centrifuge for operation. Often the dual centrifuge system like one set high speed decanter centrifuge for lower gravitational pressure solids removal; one placed lower speed or midst speed decanter centrifuge to get high gravity solids treatment; screw pump for giving the dual centrifuge are drilling to be also concluded, as well as telescopic high skid for setting up.

But for HDD field, usually clients only require decanter centrifuge in big project with much complex geomatics issue. Most of client will select GNLW452 middle speed centrifuge for proper use. Currently for HDD, the drilling depth will not so deeply as oil drilling, along with high speed decanter centrifuge is not really necessary. Middle speed along with big treating capacity regarding 1800RPM bowl speed could work perfectly for these kinds of task.