GN Solids Control is a leading brand from China for drilling mud solids control equipment, drilling waste management equipment, industry waste management and high quality replacement shaker screens. GN Solids Control major products are pit-less and zero-discharge system with drilling mud solids control and drilling cuttings management equipment, oily sludge separation unit for sludge from different sources, including but not limited to tanks bottom, oil pits, API separators, drilling rig mud system, refinery, tank cleaning, etc.

Many customers who would like to seek some proposals to help them to better manage their drilling cuttings and drilling mud generated from their drilling activity.

Recently, a drilling company contacted GN Solids Control. Their activity is mainly at onshore in a highly populated community area in a Middle East region. Currently their method is to disposed both the drilling cuttings and drilling mud inside waste pits nearby the drilling rig sites. However, the high water table of the groundwater level and current raining season is not helping and is not sustainable to maintain.

Therefore they are seeking for other ideas on how they can better manage the cuttings and mud. If possible, they want something that can help them to expedite the evaporation rate of drilling mud and drilling cuttings.

GN Solids Control recommends their pit-less system. GN shared some layouts for their reference, and helps the client to find out the best solution.

Below some equipment GN Solids Control recommend to the client for the drilling mud and drilling cuttings management to drying the waste and reduce the disposal:

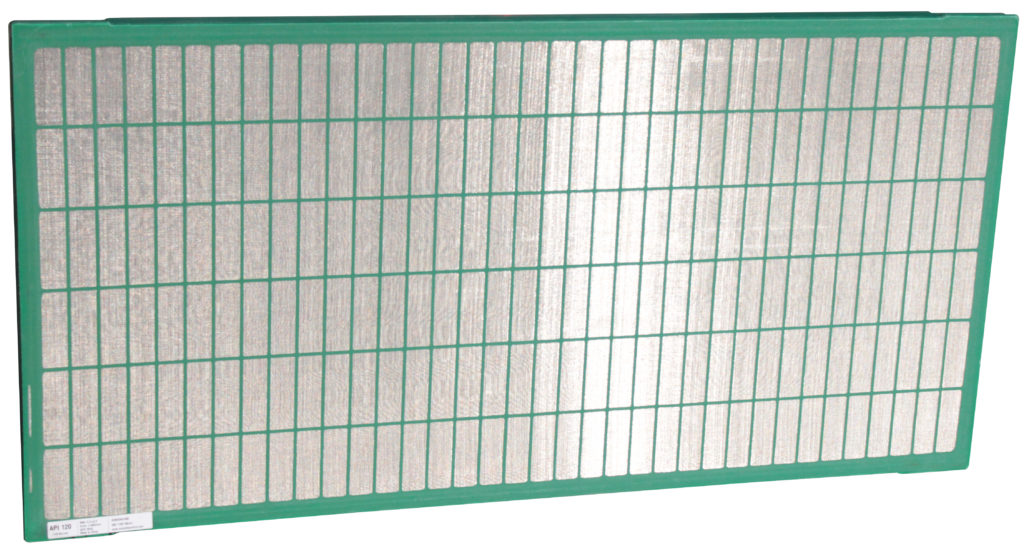

1) Screen vacuum unit. The unit is fixed under your existing shakers to further recover usable mud. Below is the working video:

http://www.gnsolidscontrol.com/video/vist-vacuum-screen-technology-for-shaker-test-video

2) High G drying shaker to recovery water based mud

http://www.gnsolidscontrol.com/video/gn-high-g-drying-shaker-and-centrifuge-for-cnpc-wbm-waste-management

3) Vertical cuttings dryer for OBM:

http://www.gnsolidscontrol.com/video/video-gn-vertical-cuttings-dryer-for-obm-working-in-middle-east

4). Stabilization/ Solidification unit for drilling cuttings drying