Sometimes, clients will come to GN to ask for solutions for their new project. Currently a customer said they were working on a project for their client on the improvement of their solid control equipment, and they ask for support from GN Solids Control. As they know GN Solids Control is a specialist for mud solids control and drilling waste management. And GN Solids Control keeps growing fast. GN promotes new equipment and technologies every year.  Their challenge is the short time to present to their client a new idea to improve solids control in their rigs. They need to submit their solutions within 3 days. GN Solids Control has rich experience for the zero-discharge mud recovery system, and offers them suitable solution very soon. Their client is looking for a new technology to increase the performance of standard solid control equipment system, improve quality treatment and consequently improve drilling operations with good environmental impact. Their idea which needs more technical support has as principal innovation from the standard process used currently to provide a separate kit including the following high performance equipment’s: 1) Two Decanter centrifuges with barite recovery 2) Combined mud cleaner with desander (means desilter + desander and shakers with one or double level). As their existing solids control system mud cleaner is very poor quality. They need to replace it. 3) Vertical cuttings dryer. 4) Small tanks to collect the fluids and transfer it to rig mud system As their clients may use oil based mud or water based mud. The cuttings type is not for sure. GN Solids Control recommend them to submitted the new idea to their client with two proposed design for OBM and WBM based on two skid:

Their challenge is the short time to present to their client a new idea to improve solids control in their rigs. They need to submit their solutions within 3 days. GN Solids Control has rich experience for the zero-discharge mud recovery system, and offers them suitable solution very soon. Their client is looking for a new technology to increase the performance of standard solid control equipment system, improve quality treatment and consequently improve drilling operations with good environmental impact. Their idea which needs more technical support has as principal innovation from the standard process used currently to provide a separate kit including the following high performance equipment’s: 1) Two Decanter centrifuges with barite recovery 2) Combined mud cleaner with desander (means desilter + desander and shakers with one or double level). As their existing solids control system mud cleaner is very poor quality. They need to replace it. 3) Vertical cuttings dryer. 4) Small tanks to collect the fluids and transfer it to rig mud system As their clients may use oil based mud or water based mud. The cuttings type is not for sure. GN Solids Control recommend them to submitted the new idea to their client with two proposed design for OBM and WBM based on two skid:  Modular 1: 1 full set of Compacted mud cleaner (desander + desilter) 2 ea feeding pump for the Compacted mud cleaner (desander + desilter) 1 full set of mud tank to collect the fluids recovered from mud cleaner, and transfer it to rig mud system. The tank system is complete with all pipelines and accessories (valves, ladders, guardrails, clean gate, walkways, etc…) within the tank system, explosion proof lighting system, and explosion proof control system for all the equipment within the tank system Modular 2: 1-skid cuttings drying system. Client can choose to use high G shaker for water base mud or VG dryer for OBM. Screw conveyors for solids transfer also showed for their information.

Modular 1: 1 full set of Compacted mud cleaner (desander + desilter) 2 ea feeding pump for the Compacted mud cleaner (desander + desilter) 1 full set of mud tank to collect the fluids recovered from mud cleaner, and transfer it to rig mud system. The tank system is complete with all pipelines and accessories (valves, ladders, guardrails, clean gate, walkways, etc…) within the tank system, explosion proof lighting system, and explosion proof control system for all the equipment within the tank system Modular 2: 1-skid cuttings drying system. Client can choose to use high G shaker for water base mud or VG dryer for OBM. Screw conveyors for solids transfer also showed for their information.

Author Archives: mudcleaner

Horizontal Mud Agitator for sale

As a mud agitator manufacturer, GN Solids Control make around 800 mud agitators a year include horizontal and vertical mud agitator. Now GN have some of mud agitators in stock for sale with c/w the following features:

• Helical Bevel Gear Box for high efficiency and high performance.

• Horizontal Mounting suitable for most of the mud tanks

• 25 HP Agitator motor for 60 HZ with speed 1800 RPM

• C-Face Explosion Proof Motor for easy installation

• 55 Deg. Amb. Temp. Rated suitable for middle east market

• 5/8″ Mounting Plate

• 8 ft.Shaft Length for the heavy duty agitation

• 3-5/8″ Agitator Shaft Dia. for heavy mud operation.

• 44″ Canted Mud Agitator Impeller for standard oilfield mud tank.

• Necessary Couplings & Bushings for connection of the gearbox and motors.

• Bottom Stabilizer for stable operation for deep mud tanks.

• 460 Volt, 3 Phase, 60 Hz. Or 380V 60HZ for most of the drilling rigs

If you have your own tank, please just send us your mud tank drawing with dimensions, we can use our software to calculate and select the suitable mud agitator for you. Besides the horizontal mud agitator, GN Solids Control also design and manufacture vertical mud agitator for less foot print installation. GN Solids Control is the first API certified mud agitator manufacturer in China, and we have our branch in Russia and USA to service the local clients with fast speed.

For last 10 years, GN Solids Control has grown up from 10 employee company to a 200 employee company with our business coverage over 70 countries and regions. Our mud agitator is polular used for drilling mud mixing tank, storage tank, and recycling tank to avoid the settlement of the solids in the mud tank. And our mud agitator is popular for oil industry, HDD, and CMB drilling as well as mining industry.

Leading manufacturers from China for high quality replacement screen

As the leading replacement screen manufacturer in the world, 2017 is a great year for GN Solids Control. GN Solids Control has done a great job through the year.

Firstly, GN Solids Control finished the upgrading of its screen production line, and also updating its high speed and big bowl decanter centrifuge products line. The updated workshops are equipped with the latest production machine and technology. And it is fully complied with the strict regulations for environment projects from Chinese government.

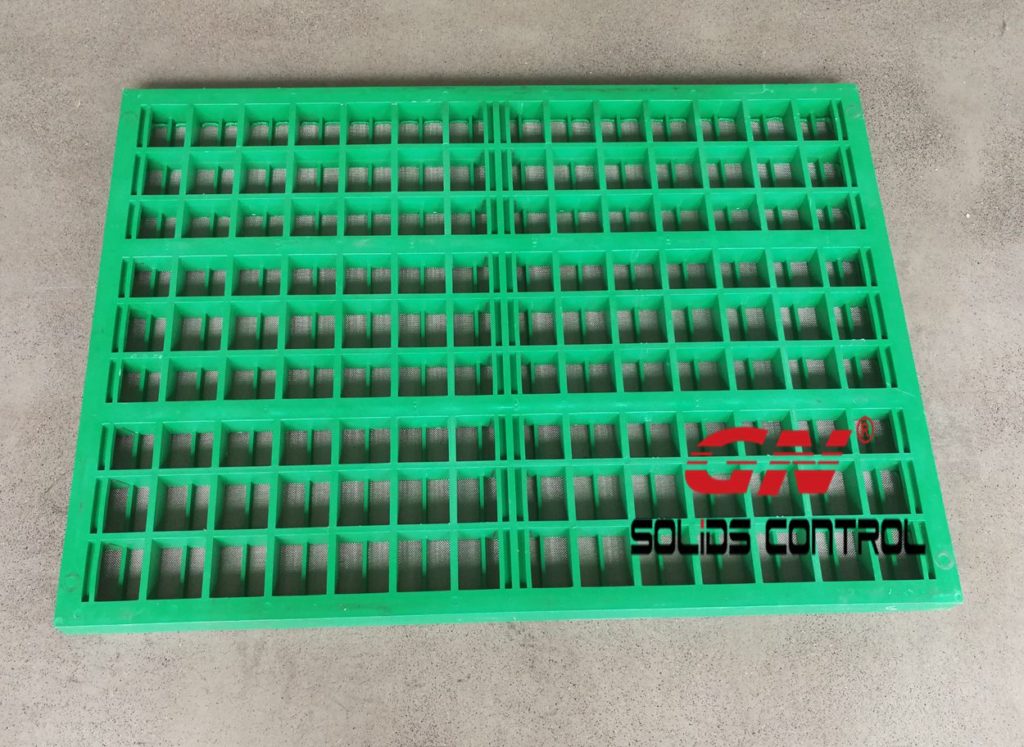

Secondly, GN developed and successfully launched its latest generation composite material shaker screen. Through 2017, GN composite material replacement screen covers nearly all the popular frame screens model. GN Solids Control own patent composite material replacement screens for Derrick shale shaker and mud cleaner are successful made out and sent to jobsites for performance test.

Furthermore, GN Solids Control got the API RP13C testing report for all its screen API Nos. from U.S lab. GN Solids Control is the only one Chinese screen manufacturer owns the testing report for screens.

GN Solids Control own patent pre-tension technology enables the replacement screens with longer lift time, better conductance, and bigger non-blank area. The better conductance and bigger non-blank area means a bigger mud flow with the same screen area.

GN Solids Control offers replacement composite material screens to below shale shaker and mud cleaner. But it is not only limited to below models:

1) Replacement Shaker Screen for MI-Swaco MONGOOSE PRO, MONGOOSE PT & MEERKAT, ALS, BEM, MD-3 series shale shaker or mud cleaner.

2) Replacement Shaker Screen for Derrick FLC 2000, FLC 500 , DP 600 and Hyperpool series shale shaker and mud cleaner.The screens are available in flat screen or pyramid screen. Composite screen is available for high quality and longer screen life.

3) Replacement Shaker Screen for NOV Brandt Cobra, King Cobra, Mini Cobra, Venom, LCM-2D, LCM-3D, VSM 300 series and D380/D285P shale shaker and mud cleaner.

4) Other replacement shaker screen for Fluid Systems 29×42, Kemtron/Elgin KPT series and other shale shaker manufacturer. Customized or OEM Shaker Screens are available.

How to feed cuttings to vertical cuttings dryer

Vertical cuttings dryer is typical processing equipment for drilling cuttings treatment, especially for oil based mud cuttings. It can reduce the oil content in the cuttings to 3 ~5%. In many counties, it is meet the standard for discharge. And the 3 ~ 5% oil on cuttings is easy for transport, and it is easy for next treatment, like thermal desorption unit.

Per different jobsite layout, and the diferent jobsite requirement, there are many ways to feeding the drill cuttings to the solidification unit.

Option 1: Screw conveyor

Auger screw conveyor is the most popular way to transfer drill cuttings to the vertical cuttings dryer, especially for onsite treatment system. Firstly, there will be screw conveyors to collection drill cuttings from solids control shale shaker, desander, desilter and mud cleaner. And then the second screw conveyor system will transfer cuttings to vertical cuttings dryer. After separation, the clean fluids recovered from solids control treatment equipment (decanter centrifuge excepted) will be feed to high speed decanter centrifuge to reduce the mud then, and then the recovered mud will be qualified for reuse again.

But if the drill cuttings is in the waste pit, or the liquid content is very high. Screw conveyor is not suitable.

Option 2: Vacuum transfer system

The vacuum transfer pump system has a wide applications. Vacuum transfer system can be used for nearly all applications. The Vacuum transfer system is a 100% air driven system. It can generate high vacuum pressure for long distance suction up to 50 m. The max. transfer length is up to 1000 m. And as there is no rotating parts in the pump. The vacuum transfer pump system allows for high solids content cuttings and big size cuttings up to 170mm. As the vacuum pressure is huge, while the vacuum transfer pump unit is used to feed for the vertical cuttings dryer, there should be some device, like cleancut, between vacuum pump system and vertical cuttings dryer.

Drill cuttings skips for the waste solids discharge

The drill cuttings skip is also called solids skips, waste collection containers, or skips. GN Solids Control can design and make drill cutting skips for the solids control system and drilling waste management systems.

Features of GN made drill cuttings skips (waste collection containers):

1) The drill cuttings skips are designed and fabracated accordance with DNV 2.7-1 standard. GN Solids Control can offer DNV 2.7-1 lifting certificate for the cuttings skips. The drill cuttings skips are capable for onshore and offshore applications.

2) The cuttings box is suitable for hazardous material transportation. The waste collection containers are completed sealed to avoid spill during transportation. And the cover is designed with an easy lock and unlock system for fast opening and closing. It is the ideal container to meet the HSE regulations for hazardous waste movement.

3) As manufacturers with his own research and development department, GN Solids Control can offer customized design drill cuttings skips to collect the drilling waste. The skips can be equipped with forklift access from all four sides, or only from 2 sides.

4) GN Solids Control designed and made drill cuttings skips (waste collection containers) suitable for container shipment. The waste collection containers can be put into container and loader with 2 layers. A full 40ft sea freight high container can load 14 ea waste material collection containers. The design can min. the sea freight cost, and also save clients inland shipping cost to move the waste collection containers.

Applications of the drill cuttings skips:

1) The drill cuttings skips can be used to collect and move the drill cuttings discharged from the drilling rig solids control system, like shale shaker, mud cleaner, desander, desilter and barite recovery decanter centrifuges.

2) The drill cuttings skips can be used to collect and move the cuttings discharged from the drilling waste management system, like high G drying shale shaker, vertical cuttings dryer, high speed decanter centrifuges,

3) slop oil, Oily sludge from tank cleaning, oily sludge from tank bottom, vessel, crude oil tank bottom sludge, etc…

See GN advanced design composite screen in Abu Dhabi oil show

GN Solids Control is a leading brand for drilling rig solids control equipment, like shale shaker, mud cleaner, desander, desilter, decanter centrifuge, vacuum degasser, centrifugal degasser, poor boy degasser mud agitator, full functional tank systems and various pumps.

Shaker screen is an important wearing spare parts for solids control spare parts. But mostly, the solids control company do not manufacturing replacement shaker screens by themselves. The screen cost is high, and the quality is not satisfied. It cannot last long. Clients have to pay much money on the screen consumption. Per the continue request of GN clients, GN R&D department takes some years and developed high quality composite material screen production line. Now GN replacement screen can cover nearly all the popular brand frame screens.

ADIPEC is one of the famous oil exhibition worldwide. It takes in Abu Dhabi UAE every year in Nov. GN Solids Control comes for the big events through years. In the past years, GN Solids Control tools his latest design decanter centrifuge for the show. Per clients’ request, this year, GN Solids Control will takes its latest design composite material replacement shaker screen for the exhibition. Clients from worldwide can come and check GN screen quality in Abu Dhabi on the oil show. Below are some of the replacement screens GN Solids Control do make:

1) Replacement screens for MI-Swaco MONGOOSE PRO shale shaker and mud cleaner, MONGOOSE PT shale shaker or mud cleaner, MEERKAT shale shaker or mud cleaner.

2) Replacement screens for NOV Brandt Cobra, King Cobra, Mini Cobra, Venom, LCM-2D, LCM-3D shale shaker or mud cleaner or mud conditioner.

3) Replacement screens for VSM 300 shale shaker and mud cleaner with different screens for Scalping, Primary, and Secondary deck.

4) Replacement screens for fluids system shale shaker or mud cleaner with screen dimension of 29×42 series shaker.

If you have interest to come for the 2017 ADIPEC exhibition, please contact GN sales team for arrangement.

River water cleaning and dredge slurry separation system

GN Solids Control offers customized and turnkey solutions on various kind of liquid solids separation project, like river water purification and cleaning system, the dredge slurry separation system.

Features of the river water purification and cleaning system, the dredge slurry separation system:

1) Normally, the capacity of the river water cleaning system and the dredge slurry separation system is big. Like 1000 m3/h or more. As the river water requested to be cleaned is near the life areas. They have to finish the separation job as short as possible to reduce the affect to nearby people normal life.

2) The particle size of the solids in the dirty river water or in the dredge slurry is not for sure. It normally contains unexpected big stuff, like shoes, rocks, household waste, etc…

3) The fine solids or ultrafine solids control is normally very high. They will increase the difficulty of the separation plant.

The normal equipment GN Solids Control will be used for the river water purification and cleaning system, the dredge slurry separation system:

1) Linear motion solids control shale shaker GNZS594G, or even the double deck shale shaker GNZS706E. Some time, the shale shaker is equipped with 2 kinds of shaker screens. Some batches of shale shakers are equipped with coarse screens to remove the unexpected big stuff in the dirty water for preseparation.

The second batch of shale shakers are equipped with fine shaker screen for the next step pre-separation, to remove the solids above 200 microns.

2) Mud cleaner combined with under flow shale shaker, desander and desilter. The mud cleaner is for the second and the third stage separation. The desander cone will remove solids over 50 microns. The desilter cones will remove solids over 27 microns.

3) Different sizes centrifugal pump to feeding for the desander and desilters. GN advanced design centrifugal pump is interchangeable with NOV Mission Magnum pump. It is the most popular pump design. It can be interchangeable with client’s old Mission pump. And they can use GN spare parts for client’s old Mission pump.

Mud agitator for drilling fluids tank and oily sludge tank

Mud agitator is popular and simple design solids control equipment. It is widely used in different tank systems, like trip tank, solids control shale shaker tank, suctions tank, storage tank, mixing tank, pill tank. Mud agitator is also be used in liquid mud plant in the drilling fluids tank, water tank and oil tank system.

Mud agitator is a based solids control equipment with simple design. Based on the connection type of driving motor and gearbox, there are 2 different designs of mud agitator.

Mud agitator design 1: Direct connection type mud agitator. For this kind of mud agitator, the driven motor and gearbox is connected directly on the tank. It is a compact design with small footprint and less weight.

Direct connection type mud agitator includes below major components:

1) 3-phase Explosion proof driving motor for zone 1 (Class 1 Div. 1) applications.

2) Heavy duty gearbox from famous brand

3) Agitator shaft. The length of the agitator shaft is depends on the tank inner depth.

4) Single lay or double lay impeller suits for the shaft length and tank inner depth.

5) For tanks with inner depth over 1.8 m , shaft stabilizer will be equipped to avoid the agitator shaft from swaying during rotating.

Mud agitator design 2: Coupling type mud agitator. For this kind of agitator, the 3-phase motor and gearbox is mounted on a skid and connected through a coupler. Advantage of coupling type mud agitator is that, it is easy to mount on the mud tank system, and easier for maintenance.

Coupling type mud agitator includes below major components:

1) 3-phase Explosion proof driving motor with coupler for zone 1 (Class 1 Div. 1) applications.

2) Heavy duty gearbox from famous brand

3) A mounting skid for the 3-phase motor and heavy duty gear box

4) Agitator shaft. The length of the agitator shaft is depends on the tank inner depth.

5) Single lay or double lay impeller suits for the shaft length and tank inner depth.

6) For tanks with inner depth over 1.8 m , shaft stabilizer will be equipped to avoid the agitator shaft from swaying during rotating.

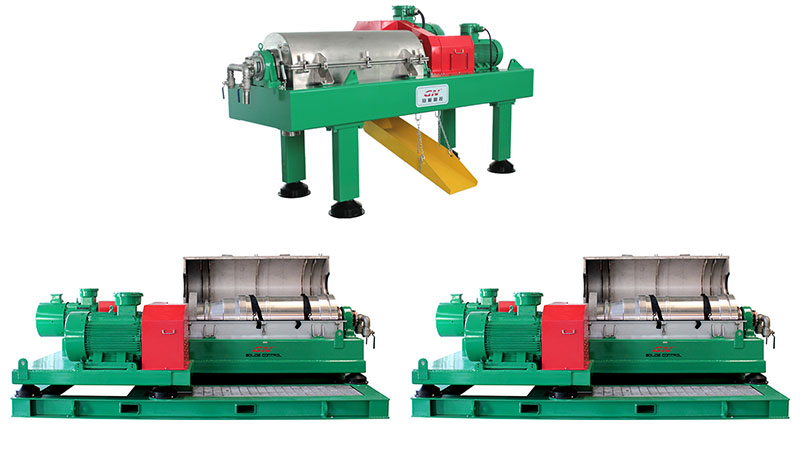

FHD centrifuge VS VFD centrifuge for waste management

GN solids control brand decanter centrifuge with VFD control panel has been used by many big oil and gas drilling companies, mud service companies, drilling waste management companies. GN Solids Control equipment and the drilling waste management equipment have been exported to 74 countries and regions till now, like U.S.A, UAE, Saudi Arabia, Australia, Argentina, UK, Malaysia, Thailand, Singapore, Romania, Brazil, Egypt, Algeria, Qatar, Kuwait, Yemen, Russia, Sudan, Morocco, PNG, South Africa, Nigeria, India, Indonesia, Korea, etc…

GN Solids Control provides 2 options for variable speed control for waste management decanter centrifuge:

Option 1 is variable frequency drive (VFD).

Option 2 is full hydraulic drive control (FHD).

Normally GN Solids Control provide centrifuge with pressurized VFD control panel with air conditioner instead of FHD, the reason is as below:

1) VFD centrifuge is more convenient for maintenance and repair. Because the electric components in the VFD is standard models, most of them are from ABB/Siemens/Schneider brand, the users can source it locally if they need to replace some parts. But the FHD should be repaired by the manufacturer if it failed to work.

2) VFD centrifuge is much cheaper than FHD. Until now there is no many good manufacturer of the core components of the FHD, we have to import, which leads the production cost very high. VFD centrifuge is more popular because it is a cost-effective option.

3) GN Solids Control had noticed to fix the inverter and other electrical components inside the VFD control panel during shipment, so you can be rest assured that they will not be loosed or fall off during transportation.

4) GN Solids Control have protection inside the VFD for Voltage and Current instability when start the centrifuge, if the change of voltage/current is in a acceptable range, it will protect the inverter from being damaged.

If you want to know more information of more about the project reference of GN Solids Control, please you contact GN team.

Telescopic decanter centrifuge skid for oil field and waste management

GN solids control is a leading manufacturer for high quality decanter centrifuges for oil & gas drilling, for fine solids separation and for waste management applications.

The specially designed telescopic skid is welcomed by GN clients as its compact design and the convenient usage. GN design telescopic skid is very user friendly, and it is conformed with the HSE requirement at jobsite. GN normal design telescopic skid is for 1 set of the high speed decanter centrifuge or big bowl decanter centrifuge. It is available for GNLW363CG-VFD centrifuge, the big bowl centrifuge GNLW453C-VFD and GNLW553C-VFD. During shipment, operators only need to fall down the telescopic skid to suit for the container shipment. During working, operators can lift the skid to a suitable height and then fix it.

The skid is complete with foldable walkways, guardrail and stairs. The normal design is with ladder, operator need to climbing up and down carefully. For GN centrifuge skid, they use stairs with guardrail at each side for security. It is easy and safety for operators goes up and down. Furthermore, the VFD control panel and the NTEZSCH screw pump feeding for centrifuges are both mounted on the skid for compact design and fast movement. If clients request, GN can offer customized design to make a telescopic skid suitable for more than 1 centrifuge models.

The skid is complete with foldable walkways, guardrail and stairs. The normal design is with ladder, operator need to climbing up and down carefully. For GN centrifuge skid, they use stairs with guardrail at each side for security. It is easy and safety for operators goes up and down. Furthermore, the VFD control panel and the NTEZSCH screw pump feeding for centrifuges are both mounted on the skid for compact design and fast movement. If clients request, GN can offer customized design to make a telescopic skid suitable for more than 1 centrifuge models.

Many jobsite people, like ADCO engineers said, it is the first time to see a telescopic skid design like GN do. They have many brands centrifuges. But no company offer a telescopic skid like GN. They are amazing when they see GN design telescopic skid with GN decanter centrifuges at their jobsite. It is very nice, convenient and safety for the jobsite people. From the telescopic skid design, they can see GN is really the one to think more for the clients. They have confidence to use any other GN Solids Control equipment and drilling waste managemnet equipment.