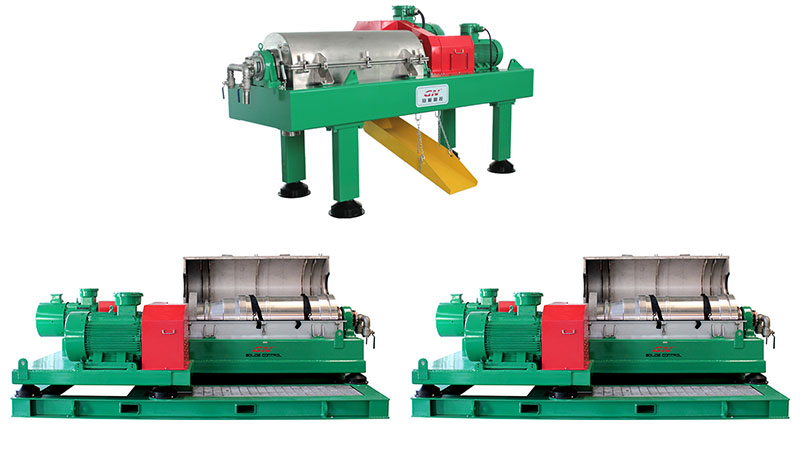

Recently, GN Solids Control engineer just finished a jobsite troubleshooting for decanter centrifuge. The problem of the the jobsite is that, the client use a very big power sand pump is used to feed for 2 centrifuges; the pipelines are controlled by valves. The pump control is separated with centrifuge control. There is no connection between pump control and centrifuge control. It is not allowed and will damage the centrifuge.

GN Solids Control comments: There MUST be connection between centrifuge control and feeding pump control.

The centrifuge itself is with overload protection. In case of overload, e.g.: the feeding flow is suddenly increased, or jobsite people wrongly open the valve to feed more mud, or the mud weight is suddenly increased, etc…The mud is over the centrifuge handling capacity. The centrifuge will be stopped to avoid damage.

In normal condition there is connection between pump control and centrifuge control. The pump feeding can be stopped immediately after the centrifuge is stopped. The centrifuge bowl is stopped rotating gradually, the internal mud is push out during the time. After the centrifuge completely stopped, operators can check the situation or adjust centrifuge settings, and start the centrifuge and pump feeding again.

But if there is no connections between centrifuge control and pump control. In case the centrifuge is stopped as overload, the pump cannot be stopped and keep feeding to the centrifuge bowl. The centrifuge stopped rotating but mud continued be pumped into the bowl and cannot come out, it will cause serious block, or even cause serious damage to centrifuge components, like damage the gearbox or bearings.

Recommended solution:

There are control components for 7.5kw feeding pump in GN centrifuge panel.

Change feeding pump to 5.5kw or 7.5kw. The pump can be controlled directly by GN centrifuge panel. There are interlock connection between centrifuge control and pump control.

Alternative solution:

If the job site is not capable to change for small feeding pump. Connect the existing pump panel control wires to GN centrifuge panel.

that the pump can be run.