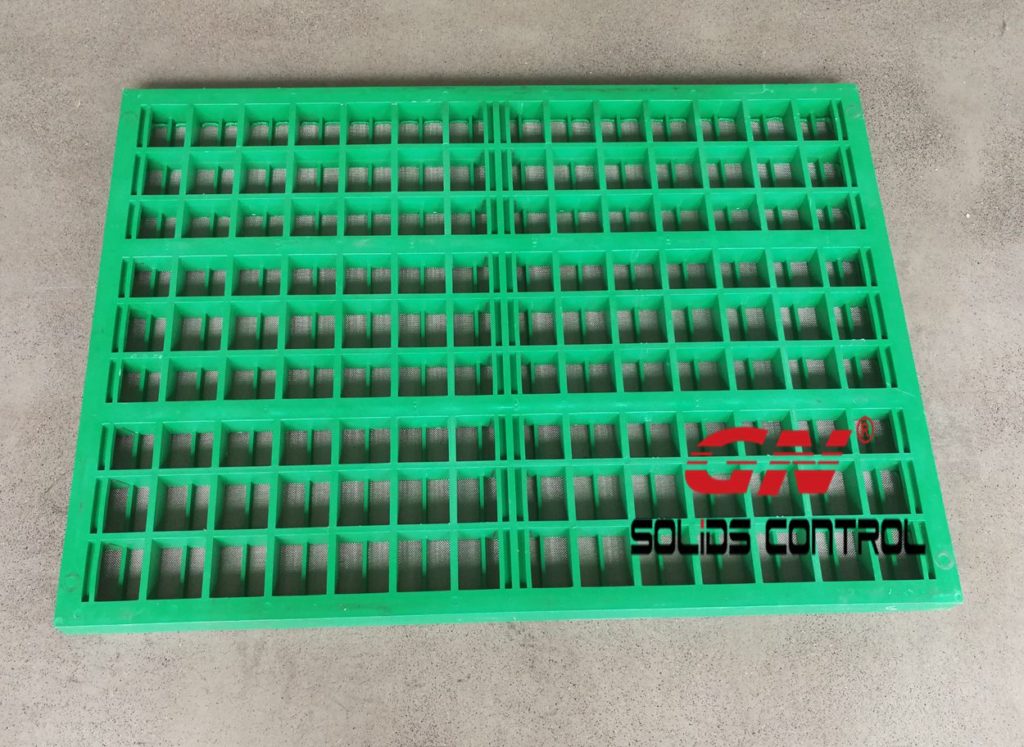

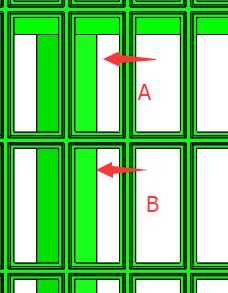

Shale shaker is the traditional process for the drilling mud recycling and separation. And the shale shaker is also the most popular processing equipment to treat drilling fluids. It utilizes shale shaker screens with different screen opening to remove cuttings and sand. The unusable cuttings and sands bigger than the screen opening cannot go pass the screen and will be discharged from the shale shaker separator, while the usable drilling fluids smaller than screen opening will go pass the screens and falls down to the holding tank under the shale shaker.

Most people may be not familiar with the Mud Cube technology, which is a technology developed by some company. Mud Cube technology is intended to replaces conventional shale shakers. There seems to be interest in the technology in many countries. The Mud Cube technology has its advantages. It can suit for some kind of drilling mud, but not suit for all kinds of drilling mud. And the cost and maintenance cost of mud cube is very high as the reason of its complicated design.

ViST Vacuum screen is developed by GN Solids Control. It is a vacuum screening unit using vacuum to recover usable drilling mud. It is not to replace traditional shale shaker. It is designed to use together with traditional shale shaker. There will be a holding hopper underneath the shaker screens of the shale shaker, and suction the usable drilling fluids with the vacuum power.

As shale shaker is still the most popular and cost effective solution, there are many popular brand for shale shakers, like Derrick, Swaco, Brandt, Fluids System, Elgin, GN Solids Control. And there are many different designs of shale shaker to suit for different applications. According to the screen Quantity, there are 2-panel shale shaker, 3-panel shale shaker, 4-panel shaker. According to the shale shaker quantity, there are single deck shale shaker, double deck shale shaker and 3 deck shale shaker. 3-panel and 4-panel single deck shale shaker is the most popular application.